-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

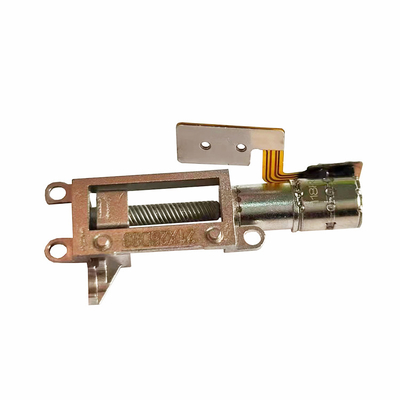

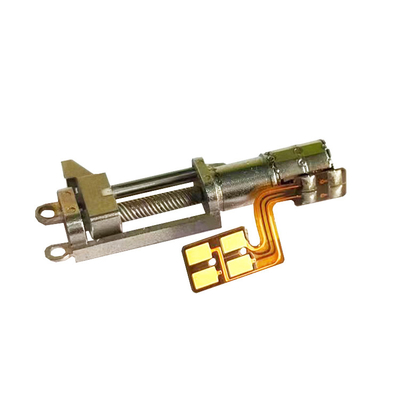

Micro Linear Stepper Motor 5mm Diameter With Planetary Gearbox Bracket Slider

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | SM05PG-Linear |

| Minimum Order Quantity | 1Unit |

| Price | $6.5~$15.5/Unit |

| Packaging Details | The product is packed with pearl cotton, and the outside is in a carton. |

| Delivery Time | 10~30 days after receiving sample payment |

| Payment Terms | MoneyGram, Western Union,Credit Card,T/T, L/C |

| Supply Ability | 100000 Units/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Motor Type | 5mm Stepper Motor | Step Angle | 22.5 Degrees/20.25 |

|---|---|---|---|

| No. Of Phases | 2 Phases (Bipolar) | Rated Voltage | 5V DC |

| Coil Resistance | 14Ω/phase | Gearbox Type | Planetary Gearbox |

| Gear Ratio | 20.25:1 | ||

| High Light | Micro Linear Stepper Motor 5mm,Planetary Gearbox Linear Stepper Motor,Planetary Gearbox Bracket Slider Motor |

||

Micro Linear Stepper Motor 5mm Diameter With Planetary Gearbox Bracket Slider

Description

This is a 5mm diameter small sized stepper motor, with a micro planetary gearbox.

The gear ratio of gearbox is 20.25:1, and it has 2 levels.

It’s attached with a bracket+slider system.

Thus it makes a linear stepper motor.

The linear thrust of the slider is at least 250 grams at 2400 PPS speed, and 5V DC.

This motor is originally developed for camera system on smart phone to move camera lens.

It can be also used on other small size electronic/electrical products, for linear movement.

Parameters

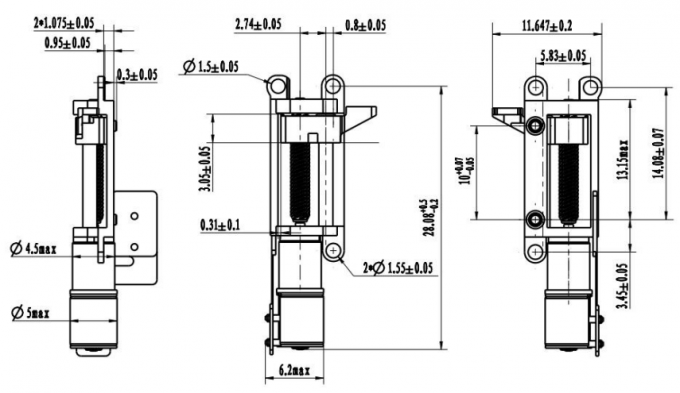

| Model No. | SM05PG-Linear |

| Motor diameter | 5 mm |

| Drive voltage | 5V DC |

| Coil resistance | 13Ω±10%/phase |

| Number of phase | 2 phases (bipolar) |

| Step angle | 22.5 degrees/20.25 |

| Gearbox type: | Planetary gearbox |

| Gear ratio | 20.25:1 |

| Lead screw type | Tr2*P0.4*6N |

Design Drawing

About planetary gearbox (MIM technology)

This planetary gearbox is specifically design drawing micro electronic products such as mobile phone, camera and other small sized products.

It’s a 2 levels gearbox, and the gears and other components inside are made from Metal injection Molding technique (MIM technology).

MIM technology use injection method to produce metallic parts, just like the way we product plastic with injection mold. It can produce high precision metal parts with small size and high precision, which is critical for a mini sized gearbox.

But the equipment of MIM technology is expensive, thus the order quantity of it is higher. Otherwise the cost on each piece of product is too long. So minimum order quantity of MIM is higher, in order to lower average cost.

About geared stepper motors

1.The power input part of the standard stepper motor is available in the form of FPC, FFC, PCB cable, etc.

2.For output shaft, we have two different types of standard shafts:D shaft and screw shaft. If a special axis type is required, we can also customize it, but there is an additional customization cost.

3.8 mm diameter permanent magnet stepper motor with 10*8 mm gear box. The gear box has high precision, high efficiency and low noise, which makes the product have good reliability.

Application

Geared stepper motors, widely used in Smart home, personal care, home appliance equipment, smart medical equipment, smart robot, smart logistics, smart cars, communication equipment, smart wearable devices, consumer electronics, camera equipment, and other industries.

Customization Service

1. Coil resistance/rated voltage: The coil resistance is adjustable, the higher the resistance, the higher the rated voltage of the motor.

2. Bracket design/slider length: If customers want longer or shorter bracket, there are special design, such as mounting holes, it is adjustable.

3. Slider design: the current slider is brass, it can be replaced with plastic to save cost

4. PCB+cable+connector: PCB design, cable length, connector pitch are adjustable, can be replaced with FPC according to customer's need.

Lead Time and Packaging Information

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by express

Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets

Shipping Method

On samples and air shipping, we use Fedex/TNT/UPS/DHL. (5~12 days for express service)

For sea shipping, we use our shipping agent, and ship from Shanghai port. (45~70 days for sea shipping)

FAQ

1.Are you a manufacturer?

Yes, we are a manufacture, and we produces mainly stepper motors.

2.Where is your factory location? Can we visit your factory?

Our factory is located in Changzhou, Jiangsu. Yes, you are very welcome to visit us.

3.Can you provide free samples?

No, we don’t provide free samples. Customers won’t treat free samples fairly.

4.Who pays for shipping cost? Can I use my shipping account?

Customers pay for shipping cost. We will quote you shipping cost.

If you think you have cheaper/more convenient shipping method, we can use you shipping account.

5.What’s you MOQ? Can I order one motor?

We don’t have MOQ, and you can order only one piece sample.

But we recommend you to order a little bit more, just in case the motor is damaged during your testing, and you can have a back-up.

6.We are developing a new project, do you provide customization service? Can we sign a NDA contract?

We have over 20 years of experience in stepper motor industry.

We have developed many projects, we can provide full set customization from design drawing to production.

We are confident we can give you few advice/suggestions for your stepper motor project.

If you are worrying about confidential issues, yes, we can sign a NDA contract.

7.Do you sell drivers? Do you produce them?

Yes, we do sell drivers. They are only suitable for temporary sample test, not suitable for mass production.

We do not produce drivers, we only produce stepper motors

Frequently Asked Question

1.Relationship between stepper motor speed and frequency:

s=f*A*60/360° [s: rotational speed (unit: RPM); f: frequency (unit: PPS); A: step angle (unit: °) ]

RPS=RPM/60 [RPS: revolutions per second; RPM: revolutions per minute]

2.How to control the direction of rotation of stepper motor?

You can change the direction level signal of the control system. You can adjust the wiring of the motor to change the direction, as follows: For two-phase motors, just one of the phases of the motor line exchange access stepper motor driver can be, such as A + and A- exchange. For three-phase motors, not one of the phases of the motor line exchange, but should be sequential exchange of the two phases, such as the A + and B + exchange, A- and B- exchange.

3.Stepper motor noise is particularly large, no force, and the motor vibration, how to do?

This situation is encountered because the stepper motor work in the oscillation zone, the solution.

A, change the input signal frequency CP to avoid the oscillation zone.

B, the use of subdivision drive, so that the step angle is reduced, running smoothly.